Angle of Perfection: A Cool Roof Coating Rehabs California Award-Winning Architecture

Spray Foam Magazine – September 2014

By Juan Sagarbarria

After it was built in 1969, Sonoma State’s old University Commons, where the cafeteria was located, earned an award for “superlative achievement in total design” from the International Design Award Program due to its use of natural light that illuminated the interior space.

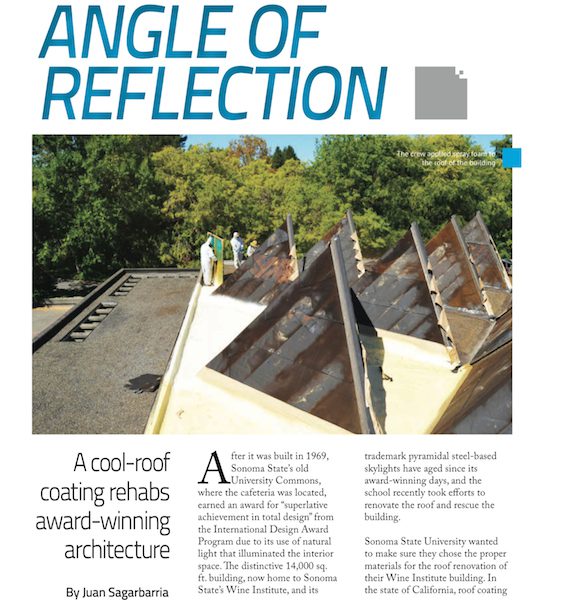

The distinctive 14,000 sq. ft. building, now home to Sonoma State’s Wine Institute, and its trademark pyramidal steel-based skylights have aged since its award-winning days, and the school recently took efforts to renovate the roof and rescue the building.

Sonoma State University wanted to make sure they chose the proper materials for the roof renovation of their Wine Institute building. In the state of California, roof coating should comply with Title 24 requirements, which stipulate that in most areas of the state the materials that are applied in a roofing application need to have a VOC content of less than 50 grams per liter.

Not only did they want the materials to be consistent with the Title 24 requirements, they wanted to make sure the roof system itself provided longevity and boosted energy efficiency for their building.

However, this intricate roof design had technical drawbacks, as its multiple-angle design presented significant openings that caused leakage into the building. The university wanted to correct the roof’s deficiencies without affecting or compromising the original lauded design.

Sonoma State brought in roof system specialist Wedge Roofing to provide a solution for these lingering roof leaks. Wedge was put in charge of the project, which entailed a spray foam installation topped with a cool-roof coating application.

“We needed to protect the roof, particularly at the transition point between the flat surface and the skylights,” said Wedge’s Gary Harvey. “A conventional roof system would not allow flashing between those two transition points and would have been much more labor intensive. The marriage of spray foam and a cool-roof coating allows for that flashing to occur, while facilitating drainage and maintaining a cool, reflective roof.”

The built-up roof was split into two levels, with the main footprint of the roof supporting a 3,200 sq. ft. upper roof area, where the skylights were located. The renovation of the upper portion of the roof consisted of several stages: the removal of aggregate and existing metal panels from the backside of the skylights, the application of spray polyurethane foam and Title 24-compliant silicone coating, the installation of granules, and the replacement of the metal panels with profile and color to match. Wedge collaborated with Premium Spray Products (PSP), which provided all the materials utilized throughout the project.

The four-man Wedge crew was outfitted with PPE consisting of Tyvek suits, gloves, and full-face respirators. Harvey explained the upper roof area was less than six feet above the lower roof area, so the crew was able to work unencumbered by fall harnesses. They removed the gravel aggregate from the roof prior to the roof system application. The crew then affixed black Visqueen sheeting with masking tape to the steel framing of the skylights to protect the glass of the skylight’s windows. Then, they applied 7-mils of PREMICOTE P75, a primer coating, to improve SPF yield on the flat surface and skylight transition area.

During the SPF application, the Wedge crew utilized a wood-frame shield with shade-cloth material that was held by the crewmembers around the spray perimeter to limit overspray from damaging surrounding areas. They installed a one-inch lift of PREMISEAL 280, a 2.8 lb. closed-cell spray polyurethane foam formulated by PSP, to the flat surface and curved-roof areas around the skylights.

To complete the roof system, the crew topped the foam with two 15-mil coats of white PREMICOTE 2100, a high solids, single-component elastomeric coating. The silicone coating is classified as an ENERGY STAR Cool Roof Coating, which allows the roof’s surface to reflect temperature-raising sunlight throughout the summer months, thereby reducing the building’s energy consumption.

At 96 percent solids, Harvey noted that the coating used exceeded the Title 24 requirements. “The elastomeric coating has a VOC content of less than 10 grams per liter, which is significantly less than what is required in our Bay Area geographical location, and the state of California at large,” said Harvey.

Harvey added that because of the high solids content of the silicone coating, its application had to be sprayed with greater pressure than average. The Wedge crew utilized a Graco 933 pump for the coating application, applying 2.5 gallons of coating at 7,250 psi with a

Graco XTR-7 airless spray gun. For the spray foam application, the crew used a Graco Reactor E-30 proportioner and a Fusion air-purge spray gun.

After the coating had cured, the crew laid down another half gallon of silicone to promote adhesion for the granule application. Then, they broadcasted C-93 white ceramic-coated granules to the roof system, providing traction and additional wear benefits. To wrap up the project, the crew installed new standing-seam ASC metal panels on the tall skylight wells.

The Wedge crew completed the project in 11 days. Harvey mentioned that staging in the middle of the Sonoma State University campus proved challenging with the heavy foot traffic, but that they were able to complete the roof system installation without complications.

The roof is now waterproofed and energy- efficient, and the roof system is backed by PSP with a 10-year warranty for products and labor of the silicone waterproofing finish coat. Harvey said that Sonoma State was pleased with the warranty because it provided a no-leak assurance where constant leaking had been a recurring issue over the years. He concluded that even though the roof might need sporadic repairs, the roof system itself will last as long as the building.

“The cool-roof application provides a seamless and leak-free barrier with comfortable indoor temperatures,” said Harvey. “It is fully sustainable, and with future reapplications, it will be the last roof system that SSU’s Wine Business Institute will ever need.”